Who We Are

At Ascendium, we turn precision into the power of execution.

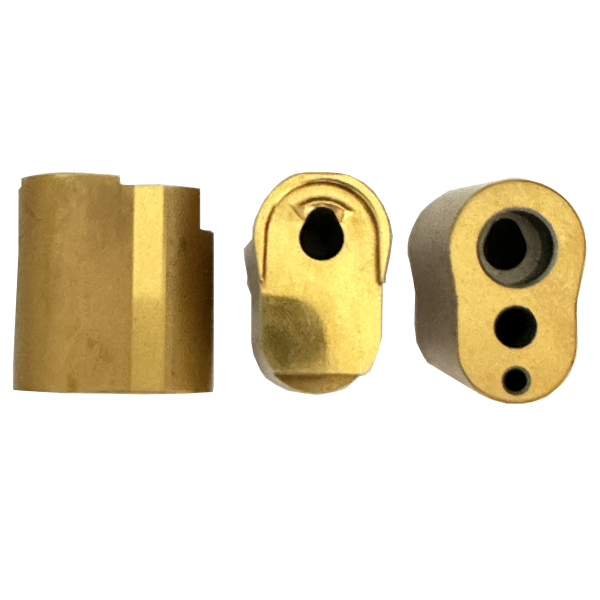

With expertise in mold development, metal processing, and mass production of components, we help our clients transform ideas into high-performance results.

Every detail reflects our unwavering commitment to reliability, accuracy, and professional quality.

Capabilities

Integrated Manufacturing Solutions for Every Precision Need

Custom Mold Design

Prototype & Testing

Inner Mold DeGating System

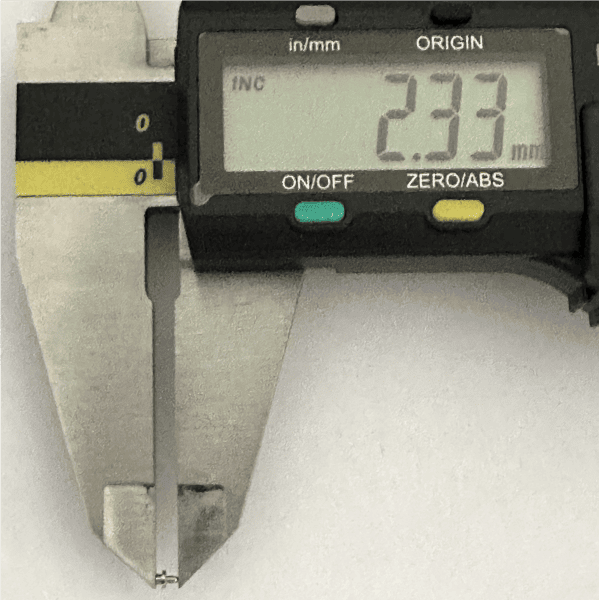

CNC Milling & Turning

Precision EDM, Wire Cutting, PG & JG

Optical-grade & Medical-grade Machining

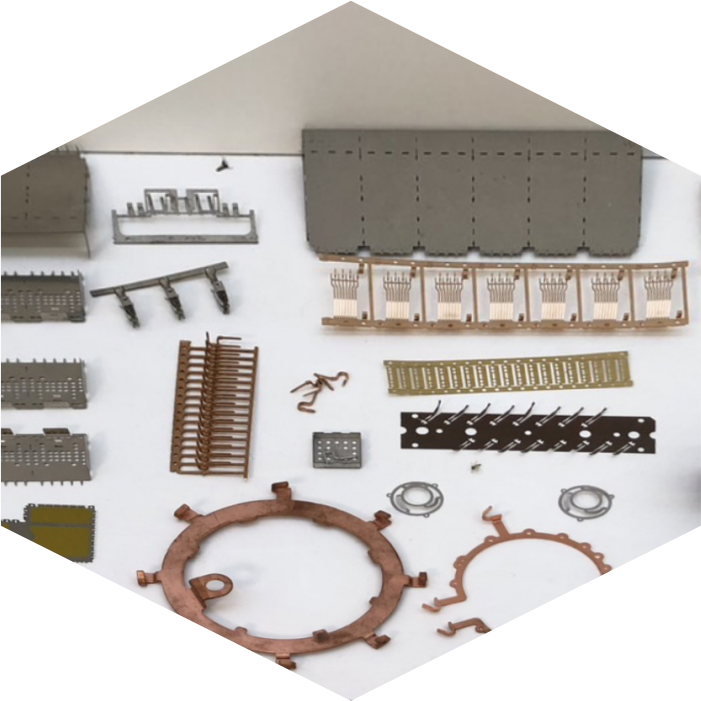

Mold Developing & Mass Production

Reverse Engineering

Engineering Mold Trial Production

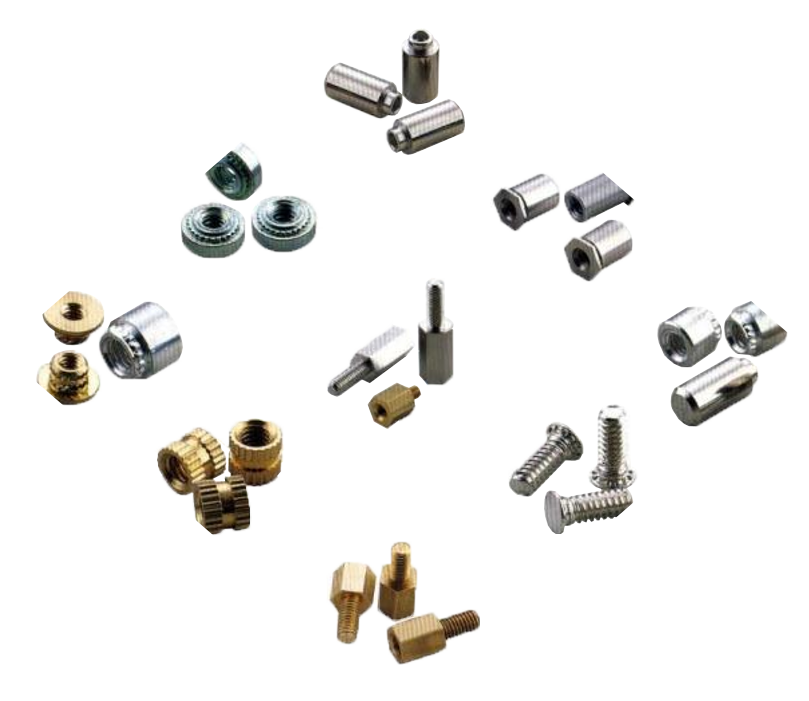

Precision Screw Manufacturing

Special Materials & Surface Treatments

Functional Fastener Development

11/20/2025

11/20/2025

11/20/2025

11/20/2025

Technical Insights

In-depth analyses of challenges, advancements, and real-world applications in precision manufacturing